Biogas & Biomethane Services

Biogas - Biomethane Services

Feasibility Study

Design and Engineering

Equipment Manufacturing

PLC system Control & SCADA

Installation and Construction

Commissioning & Startup

Efficiency optimization

Biogas drying and cooling system

A skid-mounted solution designed to remove moisture and reduce the temperature of raw biogas. The system uses advanced drying techniques and cooling processes to condition the biogas, preventing corrosion and improving downstream equipment performance. Essential for ensuring gas quality and reliability in biogas upgrading and valorization applications.

Biogas Desulfuration

After Biogas drying the desulfuration unit is designed to remove pollutants (H₂S, siloxanes, and VOCs) from biogas prior to upgrading. The system utilizes 2 or 3 activated carbon filter tanks for effective contaminant extraction.

A dust filter is installed downstream of the activated carbon filters to prevent dust emissions ensuring clean and stable gas quality.

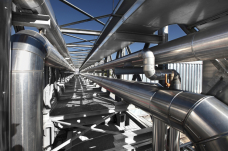

Biogas Compression Skid

A modular, skid-mounted system integrating compressors, piping, valves, instrumentation, and control systems. Engineered for optimal gas compression performance, it provides precise pressure regulation and flow control essential for biogas upgrading and injection processes. Designed for streamlined installation and maintenance, the skid ensures operational reliability and efficiency in demanding industrial environments.

Biogas Upgrading and Biomethane liquefaction

Three modular, skid-mounted systems integrating compressors, piping, valves, instrumentation, and control systems. Our partner system delivers high-purity biomethane (99%), with an advanced polishing stage achieving ultra-low CO₂ levels below 50 ppm.

Selected for its simplicity, reliability, and performance, the system converts biogas to LNG using the lowest power consumption in the market—less than 0.7 kWh/Nm³.